In this week’s post, we talk about UltronAI’s ability to dramatically streamline the operational cycle of retail computer vision.

There are ways to improve nearly every process in the world. Such improvements might be brought on simply by smart ideas and new perspectives, and other times, they involve the development or maturity of innovations that can have lasting impact. In this post, we’ll draw parallels between a historical, paradigm-shifting innovation and what’s currently happening in AI computer vision.

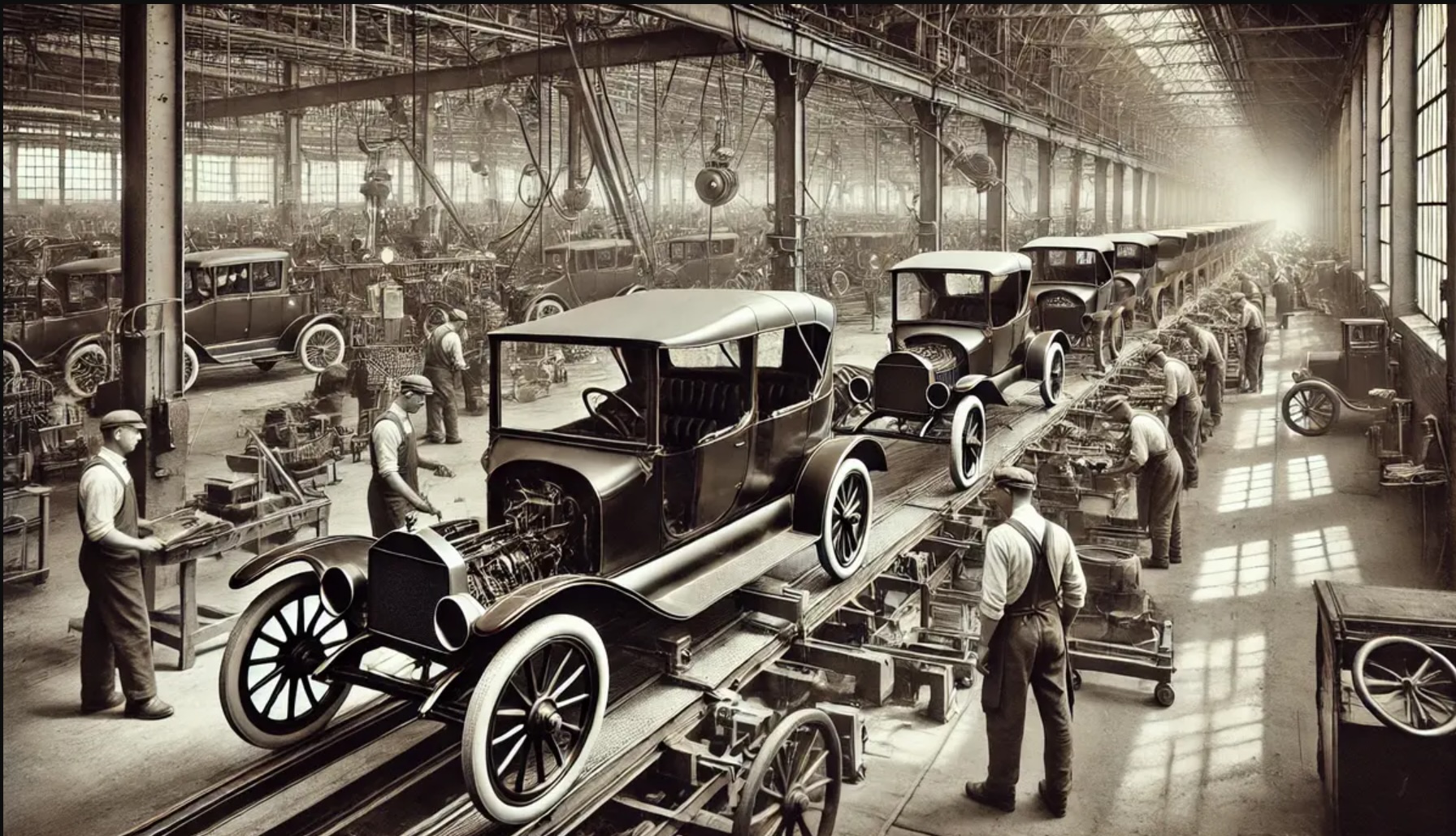

A quick history lesson

A classic example of this is from the early 20th century. Ransom Olds, the founder of the Olds Motor Vehicle Company, introduced and patented the automobile assembly line concept as a means for mass-producing automobiles. While Olds’ patented idea was a valuable improvement to older methods of manufacturing, it pales in comparison to the idea’s next evolution which revolutionized manufacturing forever.

Taking inspiration from a slaughterhouse that used a conveyor belt to more efficiently break down a carcass, Henry Ford introduced the first moving assembly line to auto production and paired it with the concept of interchangeable parts. Together, this accomplished three things:

- Productivity: Production increased by 8x while using less manpower

- Affordability: Decreased production costs enabled the price of the Model T to come down by 30%

- Safety: By keeping workers stationary instead of running all over the shop floor, the rate of injury went down significantly.

As we consider the typical AI operational cycle that we outlined last week, we can take our own inspiration from this example and draw parallels to the maturation of computer vision in retail and the impact new innovation in computer vision can have on the widespread adoption and usage of the technology.

Reducing inefficiencies in retail computer vision

The state of computer vision today can be likened to automobile production prior to Ford’s introduction of the moving assembly line and interchangeable parts. In both cases, a new concept is being introduced to an established process and has the potential for significant improvements. As computer vision is being tested, piloted, and occasionally deployed in retail environments, it has tremendous potential to address shrink by identifying intentional and unintentional theft, as well as to improve the customer experience. However, like Olds’ original stationary assembly line, computer vision has yet to achieve its potential, in part because it is rife with challenges and inefficiencies.

Last week, we dove into some of those inefficiencies as we explored the typical operational cycle of computer vision and the costs associated with the time- and labor-intensive process. Much like Henry Ford did, however, the application of new technology and concepts to the existing computer vision process can drive similar paradigm-shifting improvements to retail computer vision.

Let’s break that down into the three benefits we outlined previously that resulted from Henry Ford’s bright idea:

Productivity

For computer vision, this productivity improvement comes in multiple forms:

- Productivity in implementation: Efficiencies in the product enrollment and deployment process can dramatically reduce the cycles required to get a computer vision system “ready” for operational use

- Productivity in operations: Those same efficiencies can be applied to ongoing product catalog maintenance and management as new products are added or the packaging of existing products is updated

- Productivity in product recognition speed: Differences in foundational models and how such models are trained can result in significant differences in how quickly a computer vision system can accurately identify a given product, even against a large product catalog

Affordability

Productivity isn’t the only parallel benefit that we can identify; affordability comes into play in computer vision in much the same way it did with automobile production. And like productivity, affordability can be measured across more than one vector:

- Cost of Labor: Just like in the Ford example, the productivity improvements identified above can lead to a better overall affordability of a computer vision system. Efficiencies gained in the enrollment, deployment, maintenance, and operations processes can all result in a dramatic reduction in human hours required during the computer vision lifecycle, thereby reducing labor costs

- Cost of bill of materials: In our recent blog post on deployment costs of computer vision in retail, we outlined some of the hardware and software considerations that can drive up the cost of the physical system itself, including the cost of compute, storage, and cameras. New approaches to architecture and system design can reduce the need for costly equipment without needing to impact accuracy or speed

Accuracy

In lieu of the “Safety” benefit highlighted in the Ford example, for computer vision, the third benefit really comes down to accuracy. For computer vision, accuracy is the no-compromise requirement, especially when it comes down to a product recognition use case. That includes:

- Accuracy at volume: As product catalogs increase at size, many computer vision systems start to struggle with product recognition against that larger catalog, in part due to the overtraining methods

- Accuracy at speed: This is really the same thing as the “Productivity in product recognition speed” point above. Regardless of the size of the product catalog, computer vision accuracy can’t come at the expense of a speedy customer experience

- Accuracy in any conditions: Many computer systems struggle when attempting to operate under real-world conditions, creating delays in recognition or even failure, when working with different positions, obstructions, or in varied lighting

A promise you have to see to believe

Our original plan was to clearly outline the steps and areas where the standard operational cycle can be made more efficient. But the truth is that AI is a highly competitive industry where differentiation secrets are highly prized and closely guarded.

What we can say to you is this: UltronAI will dramatically improve productivity, affordability, and accuracy when compared against any other computer vision engine, whether commercially available or custom-built.

We’d love to prove it to you. Talk to us about starting a proof of concept today.